Your Manufacturing Command Center

Every metric, every process, every decision—visualized in real-time

How Traxs Transforms Your Operations

From raw materials to finished products, every step is tracked, analyzed, and optimized in real-time

Smart Tag Attachment

Every work order gets a smart tag that follows materials throughout the entire manufacturing process, creating a digital thread of real-time data.

Real-Time Tracking

Tags continuously transmit location, status, and process data at each manufacturing step, providing complete visibility into production flow.

Data Analysis & Modeling

Advanced AI algorithms analyze, aggregate, and model the streaming data to identify patterns, predict outcomes, and optimize processes.

Real-Time Insights

Actionable insights are delivered instantly to your dashboard, enabling immediate decisions and automated optimizations across your facility.

The Power of Connected Manufacturing

Continuous Data Stream

Each tag creates an unbroken chain of data from start to finish, capturing timing, location, quality metrics, and environmental conditions at every manufacturing step.

Intelligent Aggregation

Our AI systems aggregate data across all work orders, identifying trends, bottlenecks, and optimization opportunities that would be impossible to detect manually.

Predictive Modeling

Advanced machine learning models use historical and real-time data to predict completion times, identify potential issues, and recommend optimizations before problems occur.

Live Data Stream

Built for Modern Manufacturing

Three core capabilities that transform how you manufacture, optimize, and scale your operations.

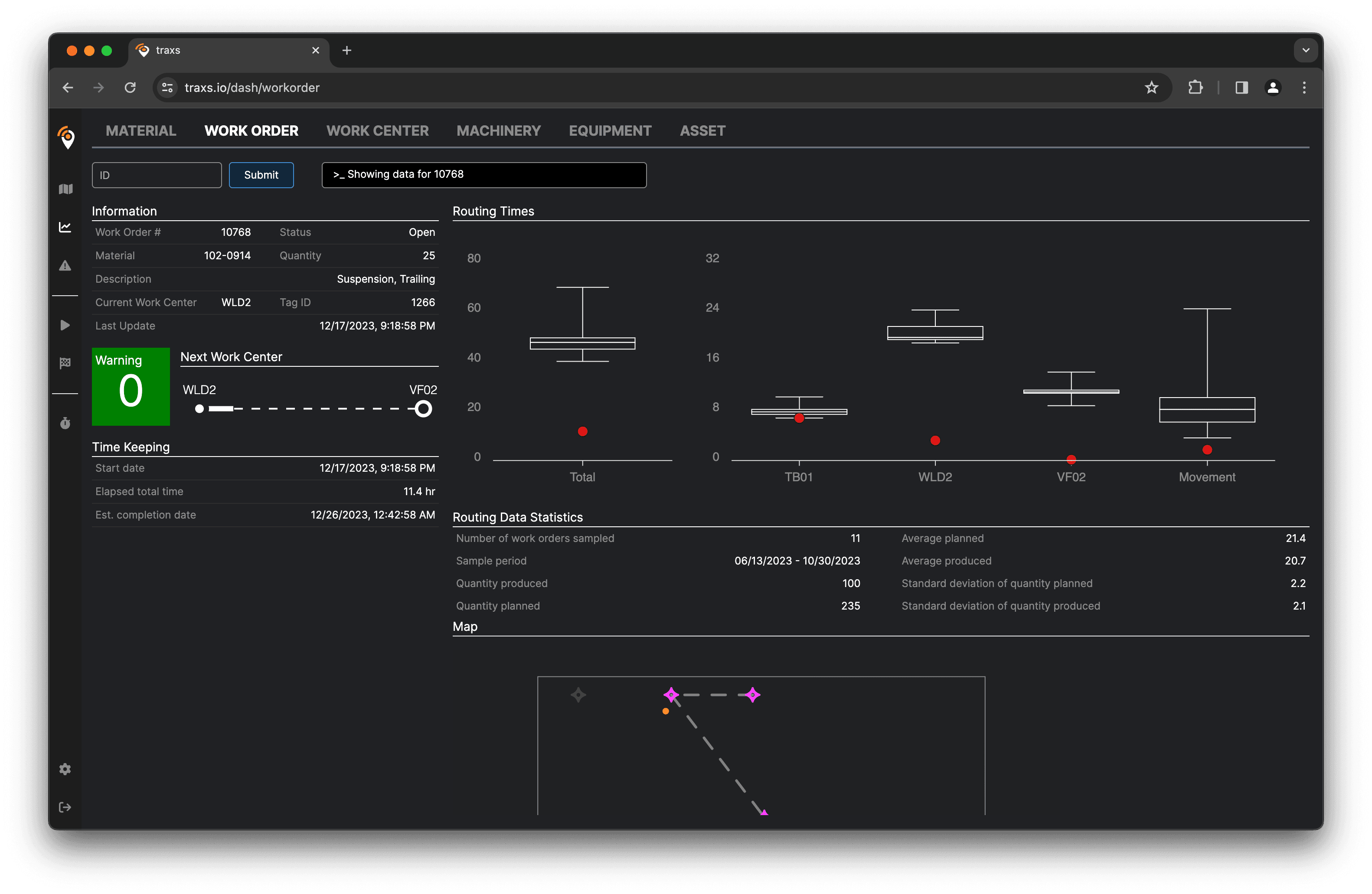

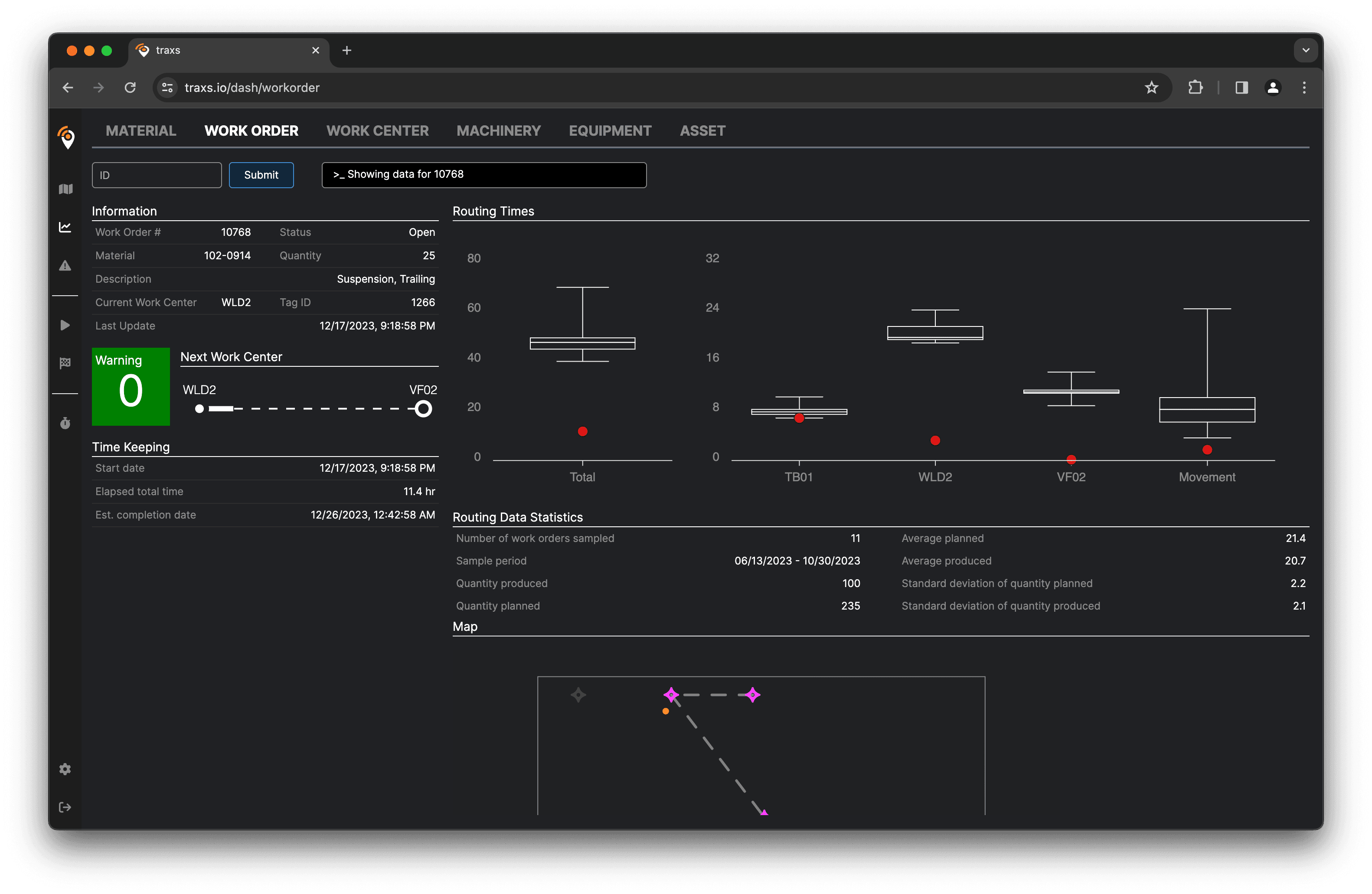

Real-time Operations

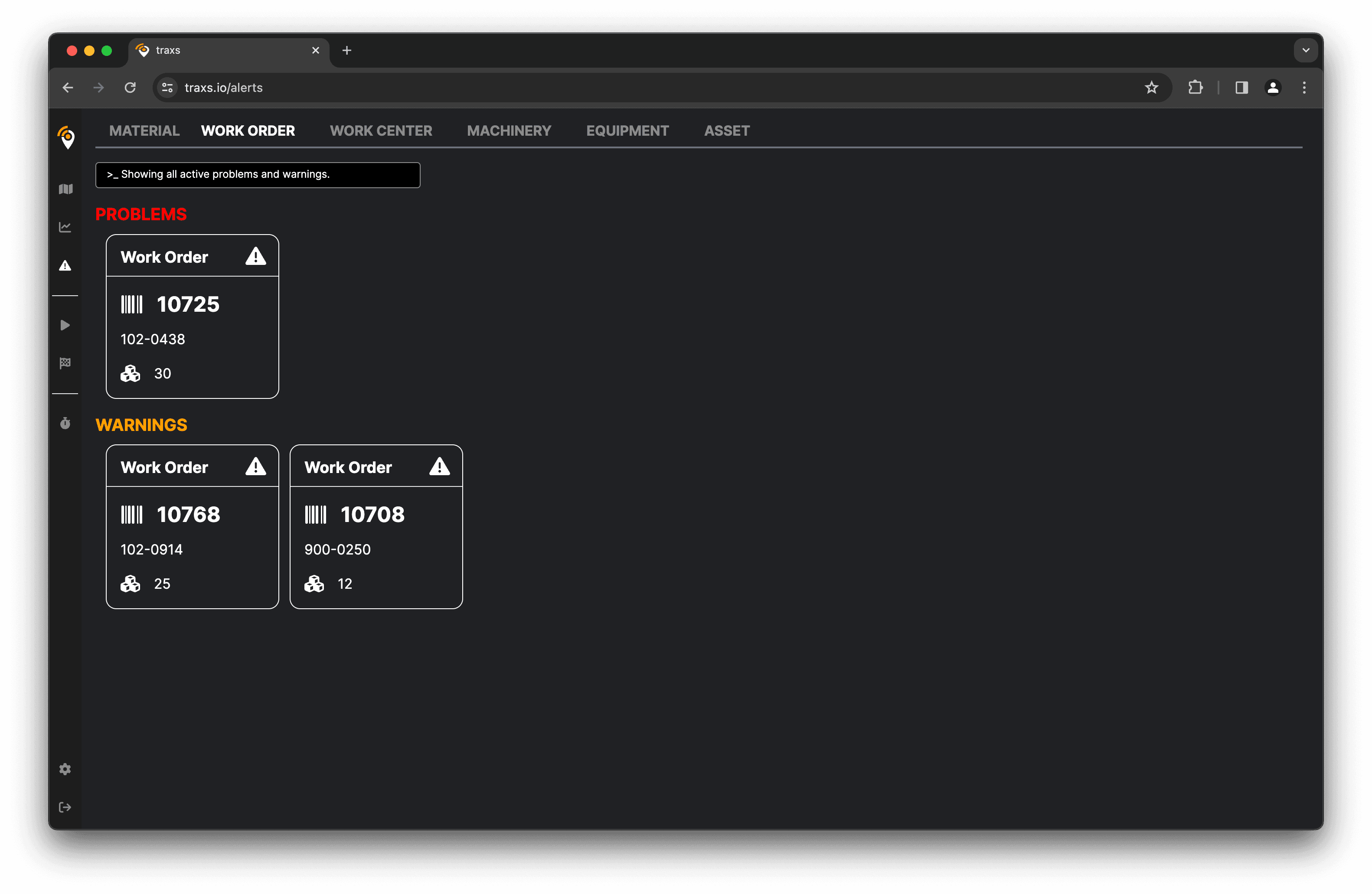

Complete visibility into every aspect of your manufacturing process with live data streams and instant notifications.

Predictive Intelligence

AI-powered forecasting that predicts bottlenecks, quality issues, and maintenance needs before they impact production.

Autonomous Optimization

Self-improving systems that automatically adjust processes, schedules, and workflows for maximum efficiency.

Zero-Risk Implementation

We handle everything so you can focus on what you do best—manufacturing excellence

Seamless Integration

Our experts install and configure everything on-site. No IT burden, no operational disruption, no learning curve.

Complete Training

Comprehensive training for your entire team. From operators to executives, everyone becomes a power user.

Lifetime Partnership

Continuous support, regular updates, hardware replacement, and ongoing optimization—all included forever.

Start Your Manufacturing Revolution

Join forward-thinking manufacturers who've already transformed their operations with intelligent automation and real-time insights.